Process

Process

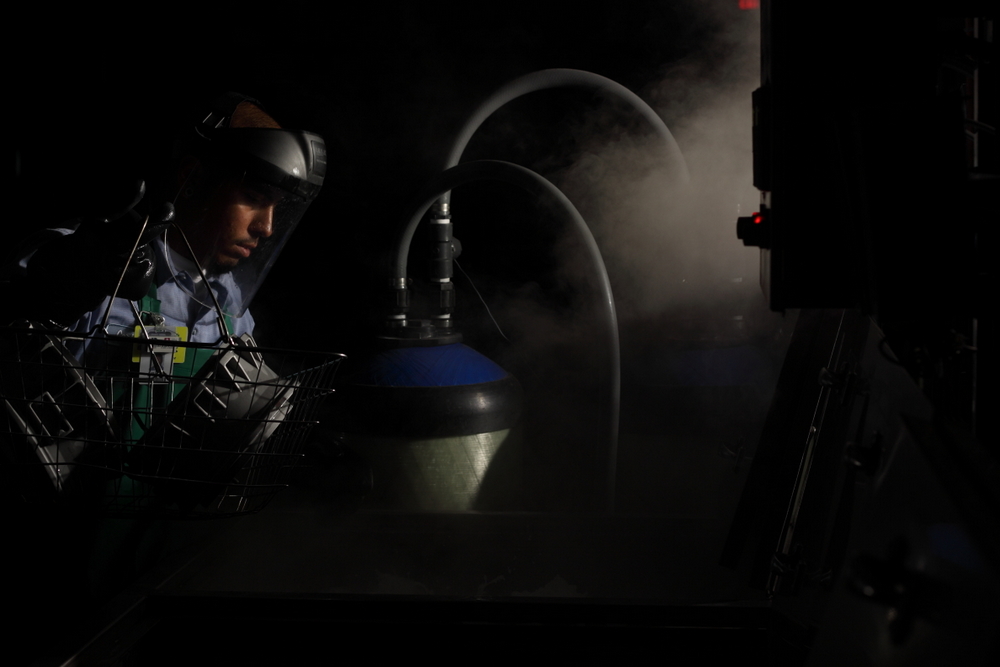

Miller Castings strongly supports integrated product development. We work closely with our customers to ensure all investment castings are designed to meet your metallurgical and dimensional requirements. Our process is designed for optimum performance and cost efficiency.

We continually enhance our SPC process with the goal of zero escapes / rejections detected by our customers. We proactively seek problem solutions without customer intervention.

We have a state-of-the-art facility, with an entirely electronic shop floor. Each work station includes work flow tracking as well as electronic techniques (instructions), specifications, and electronic storage systems to ensure complete part traceability.

Quoting

Miller Castings is one of the first manufacturers able to receive, retrieve and work with Electronic Data files from the internet and customer web sites. Miller Castings has a password protected, secure File Transfer Protocol (FTP) site specifically setup for quoting use.

Manufacturing

Miller Castings is one of the first casting suppliers to be approved using the Manufacturing Process Analysis and Control Plan Package.

Miller Castings has implemented:

- Lean Manufacturing

- Cellular Manufacturing by casting type

- Team Working Enviroment

2503 Pacific Park Drive. Whittier, CA 90601 - tel. (562) 695.0461 | © 2025. All Rights Reserved.